Choosing the Right Type of Mould Release Agent for Your Business

Mould release agents are a crucial component in the manufacturing process of numerous industries, including automotive, aerospace, construction, and consumer goods. These agents are used to separate the finished product from the mould, ensuring a smooth and efficient production process. With various types of mould release agents available in the market, choosing the right one can be a challenging task. This blog discusses the different types of mould release agents wherein we will share some tips for selecting the right one for your business needs.

Factors to Consider for Different Types of Mould Release Agents

As we discussed above what is a release agent, we must understand how to select the right mould release agent for your business. This is critical for achieving high-quality, consistent results in your casting processes. There are many factors to consider when selecting a mould release agent:

1. Type of Mould and Mould Material

Different types of moulds and mould materials have varying levels of porosity, which can affect the ability of the mould release agent to penetrate and bond with the mould surface. Factors such as the temperature and pressure used in the casting process can also influence the type of release agent that is required.

2. Type of Material Being Cast

The release agent must be compatible with the material being cast to ensure the proper release of the finished product. Additionally, certain materials may require specific release properties, such as anti-sticking or anti-slip properties. These factors must be taken into account when selecting a release agent.

3. Required Release Performance and Quality

A release agent must provide sufficient release properties to ensure the product can be easily removed from the mould without damaging its surface or compromising its integrity. The quality of the release should also be consistent, with minimal buildup or residue left behind on the finished product.

4. Environmental and Safety Considerations

Environmental and safety considerations are also important when selecting a mould release agent. Some release agents may contain hazardous chemicals that can pose a risk to workers and the environment. It’s important to choose a release agent that is safe to handle, store, and dispose of, and that meets any regulatory requirements for your industry.

5. Application Method

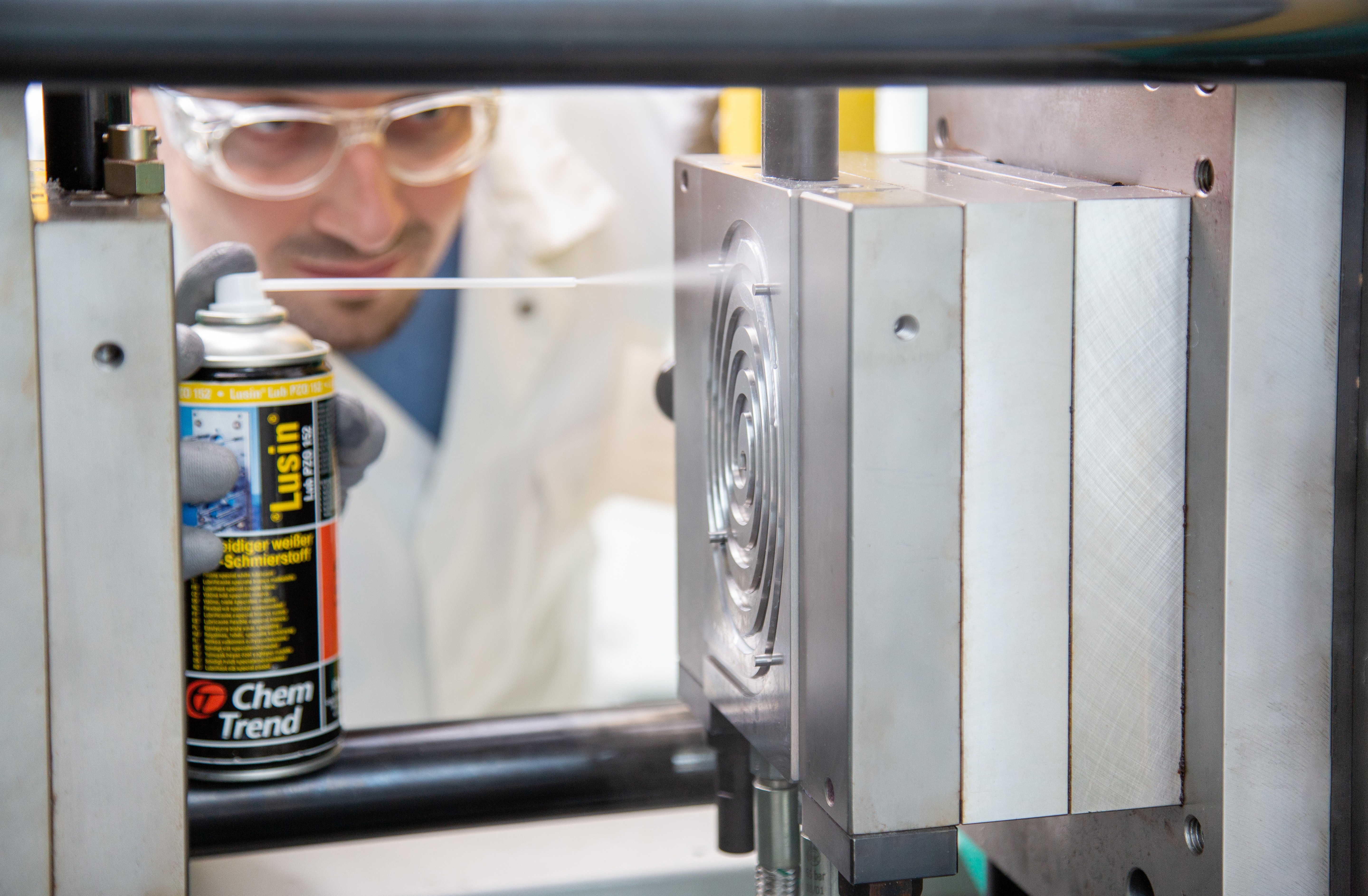

Different application methods, such as spraying, brushing, or wiping, may require different types of release agents to ensure even coverage and proper bonding with the mould surface. It’s important to choose a release agent that is compatible with your chosen application method to ensure the best possible results.

Once you have identified your needs, conduct testing and evaluation of potential mould release agents to determine which one works best for your application. It’s crucial to work with a trusted supplier or manufacturer who can provide you with expert guidance and support throughout the process. A reliable supplier can help you choose the best product, provide technical support and training, and ensure that you receive a consistent and high-quality supply of mould release agents.

Best Practices for Using Mould Release Agents

Mould release agents are an essential component in the manufacturing process of various products. Even if you are well aware of what is a release agent, it’s still important to use them correctly to achieve the desired results and ensure worker safety. By following these best practices for using mould release agents, you can ensure a safe and effective manufacturing process that produces high-quality products. We have outlined below some of the best practices for using mould release agents:

1. Proper Application and Maintenance Techniques

a) It is important to apply the release agent uniformly and evenly on the mould surface to prevent any gaps or unevenness in the release coating.

b) The frequency of application also depends on factors like the type of material being cast, the temperature and humidity of the manufacturing environment, and the number of parts being produced.

c) Regular maintenance of the mould and the release agent application equipment is also necessary to ensure optimal performance.

2. Safety Precautions when Handling and Using Mould Release Agents

a) Mould release agents can be hazardous if not handled properly.

b) It is important to read and follow the safety instructions provided by the manufacturer, wear the appropriate personal protective equipment (PPE) such as gloves, safety glasses, and respirators, and avoid inhaling or ingesting the release agent.

c) Proper storage and disposal of the release agent are also crucial to prevent any environmental or health hazards.

Choosing the right types of mould release agents is crucial for the success of any business involved in the production of casted products. Understanding the different types of mould release agents available, the advantages and disadvantages of each type, and the specific needs and requirements of your business is essential for making an informed decision.

By working with a trusted supplier or manufacturer, you can ensure that your business is using the most effective and efficient mould release agent for your specific application. Following best practices for using mould release agents and taking necessary safety precautions will also help to ensure a smooth and successful production process. With the right approach and careful consideration, you can select a mould release agent that will improve your productivity, efficiency, and product quality.