Future-Ready Mold Release Agents: What is Driving Industry Change?

Key Trends Driving Mold Release Technologies

Sustainability and Regulation

Due to the new wave of stringent environmental regulation and increasing demand for environmentally friendly manufacturing, the shift toward water-based and silicone-free mold release agents has expedited. These solutions show reduction in VOC emissions, make workers safer, and are generally aligned with the global mandate of sustainability. Chem-Trend has been at the helm of innovations in mold release agents, focusing on performance while ensuring responsibility toward the environment.

Water-Based Formulations:

Innovative emulsification technologies result in stable and efficient film formation during challenging conditions.

Silicone-Free Release Agents:

These solutions prevent post-molding contamination and coating failure problems while allowing maintenance of high-quality surface finishes.

High-Performance Chemistry Application

The demand for robust and reliable release solutions across complex geometries and diverse materials has led to breakthroughs in semi-permanent mold release agents. These chemically bond with mold surfaces, providing a dual-layered barrier for enhanced release efficacy and mold longevity.

Key advantages:

- Higher cycle times, minimizing downtime.

- Reduced mold fouling, improving overall productivity.

- Compatibility with intricate part designs in thermoset, thermoplastic, and composite molding processes.

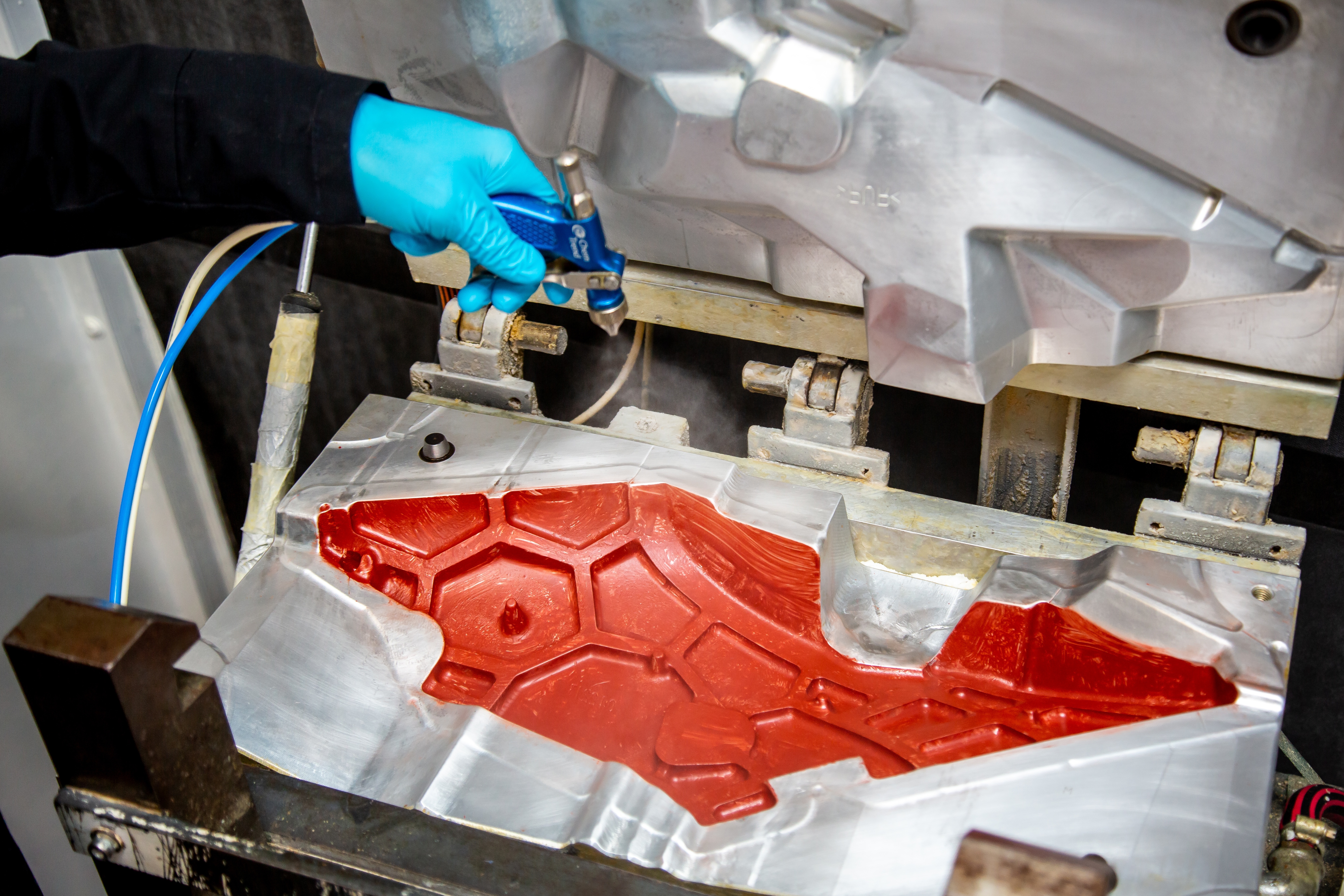

Precision Engineering in Application Methods

The precision in the application determines how to maximize the release agent’s performance. Innovative delivery mechanisms such as electrostatic spray systems and programmable multi-nozzle set-ups are improving uniformity and reducing waste. Carrier-free solutions, applied by means of electrostatic powder coating, present a noiseless, waste-reduced alternative for special applications.

Silicone Mold Release Agent: Versatility Redefined

One of the most distinguished technologies in mold release agents is the silicone mold release agent, which is noted for its versatility in terms of high-temperature process capability and intricate mold geometries. These agents are strong for maintaining the integrity of molds but leave minimal residue, thereby ensuring more effective post-molding processes like painting and bonding.

Applications:

Aerospace: Getting precise, residue-free releases critical for structural components.

Automotive: Supporting high throughput manufacturing with excellent durability under harsh conditions.

Driving Innovation in the Chemical Industry in India

The chemical companies in India are significantly contributing to the global mold release market. These firms are setting themselves up as leaders in the field by integrating advanced manufacturing techniques and sustainable practices. The adoption of cutting-edge solutions such as water-based semi-permanent agents and VOC-free carriers reflects commitment to both local and international quality standards.

Maximizing the Value of Mold Release Agents

Manufacturers today need solutions designed for specific challenges and operational efficiencies. Chem-Trend’s mold release products are engineered with the following considerations:

Thermal Stability: Ensuring consistent performance at different molding temperatures.

Chemical Compatibility: Preventing the interaction of the agent with the substrate for clean releases.

Process Optimization: Reducing scrap rates and extending mold life to enable cost-effective production.

Looking Ahead

As the manufacturing landscape continues to evolve, the chemical industry in India is poised to lead the charge in mold release innovation. From advanced chemistries to environmentally responsible solutions, the future of mold release agents lies in a synergy of performance, sustainability, and precision.

For more information on Chem-Trend’s industry-leading solutions, explore our portfolio of mold release agents or contact our experts for tailored recommendations.