Innovations in Mold Release Agent Manufacturing: What The Future Holds

Understanding Mold Release Agents

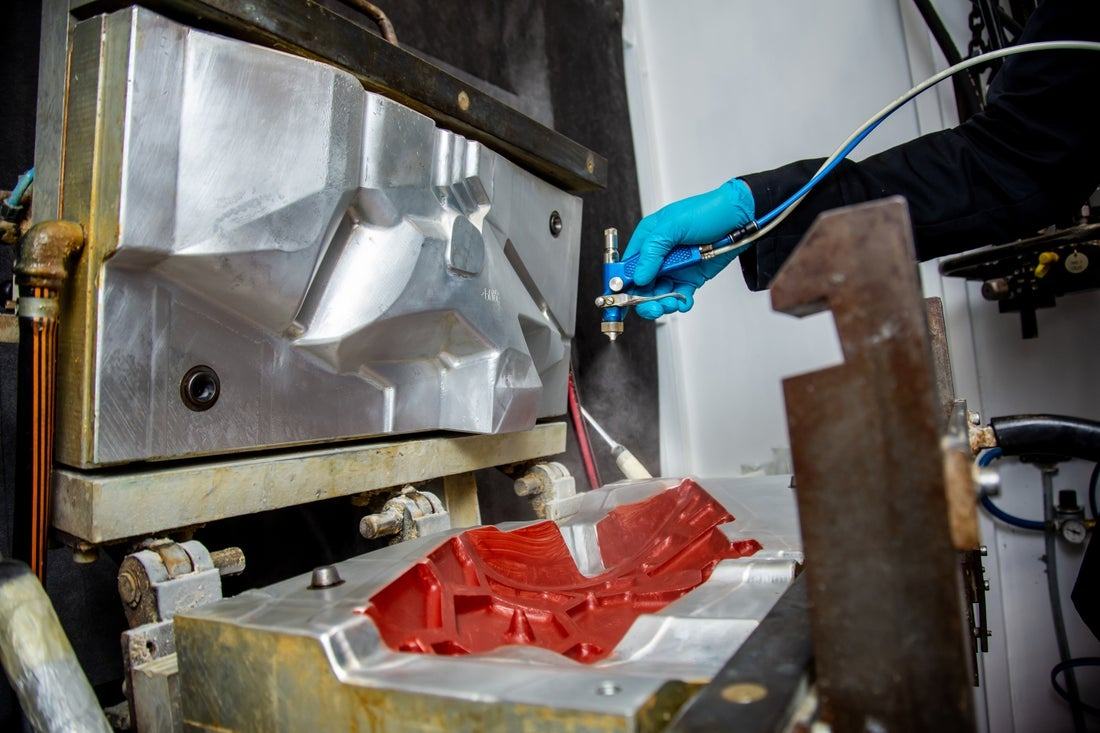

Mold release agents are chemicals specifically formulated to enable the easy removal of molded products. They play a very important role in the automotive, aerospace, construction and consumer goods segments. The success of a product really hinges on how well it releases from its mold. That’s where mold release agents come in. These agents are specially formulated blends composed of lubricants, solvents, resins, and other additives, according to various manufacturing requirements. This is to say that the right mix would create smooth releasing, which automatically will further facilitate improvement in the final product’s quality and performance.

Mold release agents are in excellent demand by the chemical industries of India, and hence, current research in this field of application is more relevant. Market research thus predicts that, by 2030, the global mold release agent market will be at an estimated $1,748 million with a compound annual growth rate (CAGR) of 4% from 2023 to 2030. Growth will be experienced due to increased die casting and rubber production besides the rapidly developing automotive sector.

Key Innovations to Make a Difference

Nano-Based Coatings

Nano-based coatings are ready to take the place of traditional mold release agents. Why? Because they provide better efficiency and surface lifetime. These latest coatings reduce friction and wear, which ultimately prevents the shortening of mold lifetimes. The products from these new manufacturing processes therefore turn out to be better-quality products.

Smart Release Agents

Another technological advancement in release agents is with the use of smart materials. Sensing devices are actually embedded straight into the material, rather than placed on the surface or above it. So how do these “smart” agents perform? They can modify their properties instantly in real time with temperature and humidity conditions. Real-time adjustments of this nature not only optimize the molding process but also lower the defects count — meaning better quality products. As the business requirement for precision continues to rise, the industry will continue to cater to the demand for more smart release agents.

Water-Based and Solvent-Free Formulations

Environmental concerns are increasing, as are the stringent regulations; thus, the industry is turning towards environmentally-friendly formulations. The interest has specifically shifted to water-based and solvent-free mold release agents. These are not only safe for workers and the environment but also greatly reduce VOC emissions by a great margin. Enterprising manufacturers are focusing their efforts on these water-based solutions that help both the ecology and health standards.

Silicone Mold Release Agents

They are uniquely designed to ensure the seamless removal of products during the molding process, eliminating sticking and preserving surface integrity. These agents, primarily composed of silicone, boast low surface tension and chemical inertness, allowing for compatibility with a wide range of materials, including plastics, rubber, and metals. Their versatility extends beyond mere release, offering additional advantages such as glazing and lubrication, which enhance the overall quality of the finished product. Available in emulsion, oil, or solvent forms, silicone mold release agents create an ultra-thin layer on the mold surface that optimizes demolding while exhibiting impressive heat resistance. When choosing a silicone mold release agent, it’s crucial to evaluate its performance, heat resistance, and safety to align with the specific needs of a chemical company in India.

Biodegradable Additives

One of the current discussions on sustainability is the use of biodegradable additives in mold release agents. These new additives play an important role in reducing the negative environmental impacts while at the same time increasing the efficiency of release. Is it not amazing how a seemingly simple component can indeed make a mighty difference? All this trend in using these additives is attracted by strict regulatory requirements aimed to protect our planet. Among companies who care about their sustainability, Chem-Trend stand out head and shoulders above others. Their eco-sensitive products are increasingly forming part of the ingredients of major businesses globally.

Industry-Specific Solutions

Customized solutions for individual industries are fast becoming the mainstay in the mold release agent market. Manufacturers are already actively engaged in developing release agents tailored to lightweight materials and high-performance composites, which are gaining considerable demand. Isn’t it interesting how important these tailored solutions have become? In nearly every industry, customized formulations lead to better-quality products with fewer defects, highlighting the importance of finding the right fit. Chem-Trend, a chemical company in India is a chemical house that specializes only in industry-specific solutions. They formulate products that does not just add quality and performance to a product but rather meets unique needs of different sectors across the country.

Market Dynamics and Growth Opportunities

New Developments

Let’s look at some key trends shaping the mold release agent market:

- Environmental Regulations: Growing regulations on exhaust and chemical safety mean manufacturers are coming under increased pressure to lower their environmental impact. This, in turn, is driving them to be both greener in process and formulation, and signifies a much broader shift in the industry toward sustainability.

• Technological Advancements: Demand to evolve the manufacturing processes by using 3D printing and advanced molding techniques are increasing day by day.

Rising Demand For Lightweight Composites And Plastics: These lightweight composites and plastics enjoy increasing demands wherever saving in weight makes their value acceptable. People demand better quality surface finishes, and effective mold release agents go a long way in that direction.

Regional Perspectives

The Asia-Pacific region, particularly India and China, are mainly considered growth contributors in the mold release agent market. Rapid industrialization and the newly emerging automobile sector in these countries open doors to creating an environment for ecologically friendly mold release agent growth. This growth shall be observed with increased demand from local manufacturers for improved production efficiency and quality of products.

Challenges and Strategic Growth Opportunities

The mold release agent market comprises a lot of opportunities for growth. However, several issues need to be addressed by the manufacturers:

1. Environmental and Health Issues: As industry regulations build up their aggressive stance on the use of chemicals, companies must invest in research and development to provide consumers with safer formulations, which are also greener.

2. Cost Pressures: This economy tends to remain vulnerable towards fluctuation in raw material costs and faces absolute compulsion to innovate continuously. The innovation is aimed at sustaining the pressure of manufacturing eco-friendly products within budgetary constraints. It is an increasingly daunting task for strategic planning and resource allocation.

3. Technological Complexity: In manufacturing, a lot of materials are involved and various processes are employed; hence universal solutions meeting the vast requirements of industries may pose difficulties.

4. Competition and Differentiation: Markets are quite competitive; hence, the point of innovation and quality remains a source through which one can try to differentiate oneself among competitors.

Capitalizing on Opportunities

To overcome challenges and achieve growth objectives, manufacturing firms should attempt the following strategic growth opportunities:

- R&D Investment: Innovation in formulations along with sustainable practices differentiates a company today in a crowded marketplace.

• Focus On Emerging Markets: Developing custom solutions that cater to local demands can be a practical way for manufacturers to penetrate new markets.

• Collaborative Partnerships: Through either partnerships or acquisitions, new markets are created. As more distribution networks open up, so will the growth opportunities.

• Sustainability Initiatives: Environment-friendly products that are biodegradable will attract conscious environmental consumers and thus increase market demand.

ChemTrend: Innovating Mold Release for a Sustainable Future

The manufacturing of the mold release agent holds great promise for future growth. Innovation, sustainability, efficiency, and flexibility are the prime focus. No wonder, responsible companies such as ChemTrend invests heavily in advanced technologies and sustainable practices. Solutions that transform the mold release agent market would drastically improve the industry.

Steady innovation and greater commitment to sustainability makes the chemical industry in India poised for faster growth in the years ahead and serving the future generation by promoting sustainability.